Product Description

AC Three-Phase Four-Line 2-Stage Line Filters are available off-the-shelf from 0.5A to 800A.

However, these designs can be easily modified to meet your specific high current needs up to 1,000 A.

Please contact FILETEMC for your specific requirements.

100% of the products will be inspected before dispatch.

We can provide in-time quotation. Samples can be ready within 3 days.

The most important thing is that our leadtime can meet the customers' requirement.

Features and Benefits of AC Line Filters:

-

Suitable for three-phase plus neutral line power supply.

-

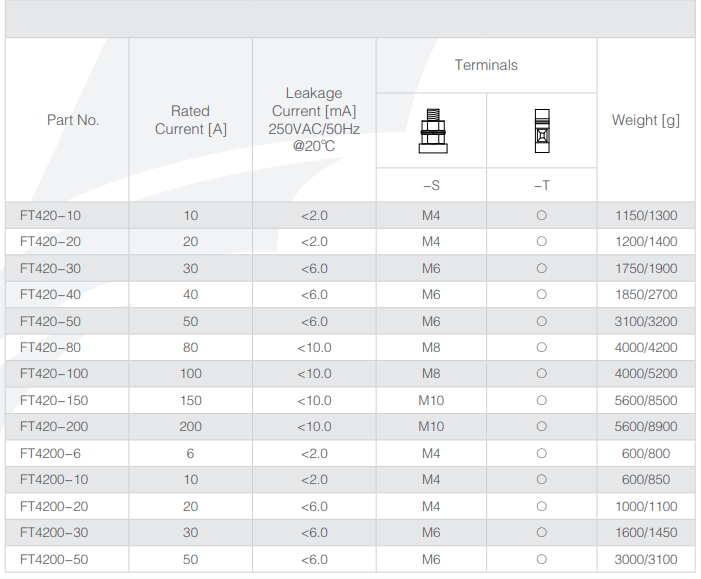

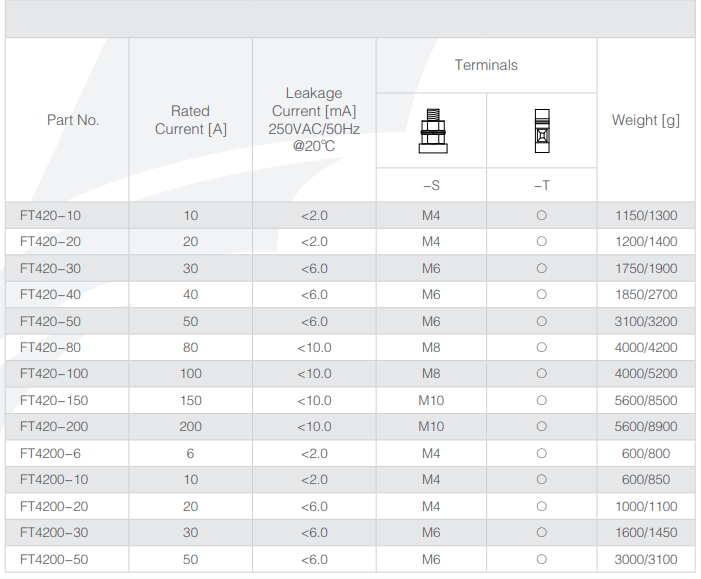

FT420 series are two-stage common mode high performance three-phase four-line filters.

-

FT4200 series are two-stage filters comprising one common mode and one differential mode with enhanced

filtering effect of the differential mode interference.

-

Excellent common and differential mode filtering effect for interference from 10KHz to 30MHz.

Typical Applications of RFI Filters:

-

Machine tools

-

Power inverter

-

Frequency conversion equipment

-

Mechanical equipment

Automation equipment

-

Medical device and other electric applications

with three-phase and neutral power supply

Important Note on AC Power Line Filter Application:

1. Storage of EMI Filters:EMI filters mustn't be left out in the heat of the sun or exposed to the rain, it should be stored in warehouse

with good ventilation, surrounding temperature between -30℃ and +65℃ , the highest relative air humidity

lower than 90%, and no corrosive liquid or gas.

2. Installation of EMI Filters:

-

EMI filters should be installed at power input, and the line inside the chassis be as short as possible to

reduce radiated interference.

-

Both input and output lines of EMI filters neither be intersected nor be tied up by string.

-

Make sure the mounting flange fully grounded, and keep the ground cable as short as possible if filters are

connected to other equipment.

-

If the terminal is stud, please use two spanners to fasten the screw nut when connecting to avoid stud

rotating and thus causing changes to the internal circuit and consequently leading to filters arcing, short

circuit, broken down or the filtering effect worsened. First use spanner1 to fix the screw nut near the metal

case, then use spanner2 to tighten the screw nut in front( shown as Figure1), otherwise the terminals may

be damaged. Apply the same for the connection of other phases.

-

Keep the tools fastening the stud be vertical to the metal case of filter when installing terminal block filters

( shown as Figure2 ), must not tilt( shown as Figure3 ), otherwise the terminal blocks may be damaged.

3. Reminding and Warning:

Please read all the safety warnings and instructions before installing filters and putting them into use:

-

Don't take terminals as supporting point when moving filters to avoid the terminals distortion, loosening or

broken.

-

The protective earth connections shall be the first to be made when the EMC filter is installed and the last to

be disconnected.

-

Filters generate leakage current, please make sure they are well grounded before putting into operation.

-

If the rated current is higher than 50A, we recommend grounding by the earth terminals but not only through

the metal case of filters.

-

Danger of electric shock: EMC filters contain components that store an electric charge. Dangerous voltages

can continue to exist at the filter terminals for longer than five minutes even after the power has been

switched off.

The working conditions of EMI filter should comply with the technical parameters stated on the label, over

voltage or overload could cause damage to filters. It is suggested to take proper over current protection

measures.

-

Current drop occurs when the surrounding temperature rise, fail to follow the current drop requirement may

lead to impermissible exceeding of the component temperature, as a result the service life of filters will be

shortened after long time running.