| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 2 Piece/Pieces |

| Delivery Time: | 7 Days |

Basic Info

Model No.: FT110D FT111D

Rated Voltage: 110/250VAC

Climatic Category(IEC 60068-1): 25/085/21(-25℃ /+85℃ Damp Heat Test For 21 Days)

Operating Frequency: DC

Test Voltage: 500VDC, 3S(line-line); 500VDC, 3S(line-l

Rated Current: 0.5~300A@40℃

Additional Info

Packaging: Carton

Productivity: 500,000pcs annually

Brand: FILTEMC

Transportation: Ocean,Air

Place of Origin: Jinan

Certificate: ISO9001, CE, UL, TUV, RoHS

HS Code: 8548900001

Port: Qingdao,Tianjin,Beijing

Product Description

Most power supplies operate using DC voltages.

DC Motor EMI Filters allow DC and low-frequency currents to pass through while blocking harmful high-frequency currents.

This allows for the device to work correctly by diverting unnecessary noise.

This series carries CE and UL approvals and offers a current range from 1 to 300A with nominal voltage up to 1000 Vdc.

Introduction of DC Motor Line Noise EMI Filter:

Rated current: 0.5~300A

Working voltage: 0~250VDC

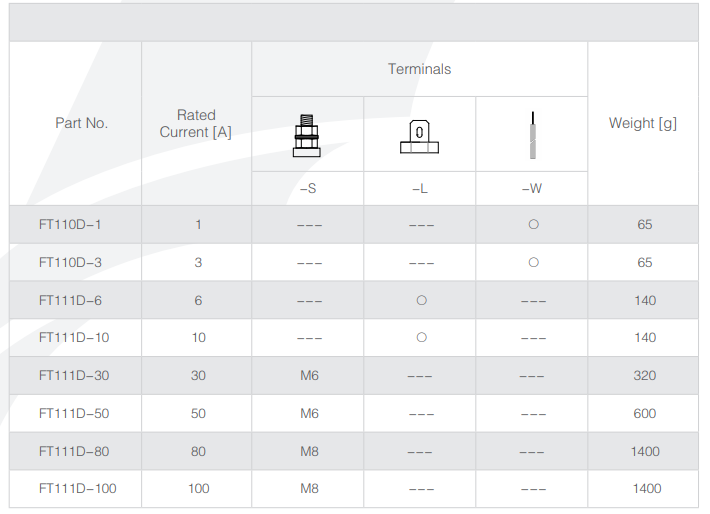

Various terminals: wire, solder lug, stud

Custom specific versions on request

Typical Applications of DC Motor Line Noise EMI Filter:

Suitable for switch power supply, SPC exchange and other DC electric device

Features and Benefits of DC Motor Line Noise EMI Filter:

Technical Data of DC Motor Line Noise EMI Filter:

1. Storage of DC Motor Line Noise EMI Filter:

The DC EMI filters mustn't be left out in the heat of the sun or exposed to the rain, it should be stored in warehouse with good ventilation, surrounding temperature between -30℃ and +65℃ , the highest relative air humidity lower than 90%, and no corrosive liquid or gas.

2. Installation of DC Motor Line Noise EMI Filter:

Requests for samples of any catalog item are available for engineering evaluation Free of Charge.

All EMI Filters are RoHS compliant and approvals held include CE, UL,cUL and TUV.

All quality control procedures are fully documented and available for review. FILTEMC is ISO 9001 compliant.